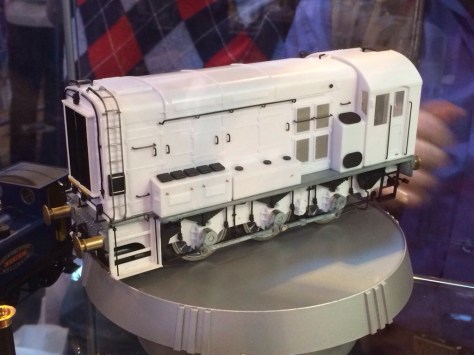

While I cannot find anything of use (at all) on the Dapol site on the new UK Class 08 shunter they’re releasing sometime during 2016. You can read more about it on Tower Model’s website: http://www.tower-models.com/towermodels/ogauge/dapol/dapolloco/class08/index.htm

The nuts and bolts of the model are as follows:

- Fine cast metal coupling hooks and chains.

- Finely moulded body with many separately added fine details.

- Etched name plates where applicable.

- DCC ready with PluX 22 pin socket for control of all aspects of running.

- Cast wheels with fine relief and appropriate colouring.

- Tungsten chassis and all wheel pick-up.

- Tooling designed to allow production of alternate models in the future.

- Powerful 5 pole skew wound motor and flywheel for superior running and performance

- Accessory bag with spares and other added detail.

Surprisingly, the model will be reasonably affordable for those of us overseas (not in old Blighty). Considering that we don’t have to pay the VAT, even with shipping, the base cost is only about the $AU355 dollar mark – depending on the currency fluctuation. And that is not that bad. Anyone interested in helping “The Andrew Martin Inaugural O Scale Loco Conservation and Operating Fund”? This will make sure that I can properly curate and run one of these little beauties for all time! And you will get your name engraved on a scale sized plate on the side of the locomotive; And you’ll get to come over and run the loco too on running days! You may have to pay your own airfare, although you can sleep on the couch for free!

While I’m waiting for the money to arrive zip on over to the Albion Yard blog to see the images. Outstanding stuff Dapol. But should I have to go to Tower Model’s website to see more about your model? Really?

Category Archives: O Scale

Broad O scale category of modelling articles

Site seeing: October 03

I love the size, and the presence that O scale models have. While cruising around on the MRH forum the other day I came across the blog of Jack from France (SVJRR) whose modelling is just outstanding. And so onto today’s site.

Site 1: O scale – Updating some Atlas/Roco cars

Image 1: Jack’s completed rebuild and respray of the Atlas/Roco 1970s Boxcar

Jack, whose English is very good for those who might be worried, steps you through a tutorial on how he updated some of the 1970’s Atlas O Scale cars (actually made by Roco in Europe) into modern-day equivalents.

As I have around 10 of these cars sitting quietly in my stash his tutorial came about at exactly the right time. The work is simple (and not surprisingly mirrors the work I am doing on the Gondola build at the moment.

I know that the cars are not exact matches for specific prototypes, although they are very close, but they allow you to get up and running quickly with little effort beyond grabs, steps and a repaint.

Site seeing – August 22nd

Over on Gene’s P48 blog I’ve made mention of the build he’s had going on for some time. In fact the list of articles for the Wilson Reefer build is can be found by following this link to Gene’s website. You can skip to the last part and see the painting directly using the link below.

Site 1: Reefers in Paint

With Gene’s build being complete the paint is now going on. I’ve really enjoyed watching the build and some of the techniques that Gene has used.

Site seeing – August 10th

Yesterday was all about passenger service; today is all about freight. Chris Gilbert pointed this video out, on his YouTube page. However the producer is ChicagoJoe28. But enough words let’s get to the video.

Site 1: Mike switches Batory Foods Chicago Terminal railroad

Video 1: Batory Food Switching on the Chicago Terminal

A little history

Located at 2234 W 43rd St, Chicago, IL 60609, Batory Foods began trading in 1979 when Abel Friedman opened Chicago Sweeteners. As a single source supplier of basic food ingredients such as sugar, flour, salt, starch, milk, oats, honey and corn syrup. Chicago Sweeteners expanded its product offering over time, as food manufacturers sought to develop healthier products.

With success in the greater Chicago market, the Company brought its broad line model to food manufacturing centres around the country. Some of the growth came with the original business; some by way of acquisition with:

- Sugar Incentives bought in 1995,

- Ingredients International in 2006,

- Quality Ingredients in 2008,

- LSI in 2009,

- Industrial Ingredients in 2009,

- Massey Fair in 2011, and

- Mac Source in 2011.

Recently, the various names were consolidates into the single name: Batory Foods.

The layout idea

The site’s switched as an Inglenook. The two on-site spurs lead to undercover augers (I’m assuming here of course) for unloading powdered or granulated product.

Image 1: The unloading spots (courtesy of Bing)

The storage track goes to other industries further down the track, but does not show recent use from my quick look. The loco has to push the cars into the site so you have a simple, prototypical Inglenook that won’t take up too much space. It is small enough that you could model any date from 1979 on in HO, S or O scale.

SCORE! What are your thoughts?

Thanks to Chris Gilbert for the vision, and to ChicagoJoe28 for filming it.

Site seeing – June 1

Over on Gene’s P48 (Proto 48 – Fine US O Scale) blog he’s building the first of a series of Wilson meat reefers. Today’s first post provides some information about the series of cars that he is building. The following articles are bringing the build process up to date so far.

While the articles are about building a car in American Proto 48 O Scale there is much to be learned about scratchbuilding from gene that can be applied to any scratch build or bash project you might have in the work. Take the time and take a look around. I’ll be applying the techniques Gene’s been writing about to my future modelling work.

Site 1: Commentary – Meat Reefers [+ Link Here]

This article provides a run down of the types of reefer and some of the inaccuracies in existing models of this type.

Site 2: Modeling: Meat Reefers [+ Link Here]

This is the first article on building the reefer. The focus of this article is on the basics of the design and starting the body.

Site 2 Modeling: Next step on the reefer [+ Link Here]

The second article focuses on the steps to complete the basic body. This includes some really great ideas on how to complete the sub-roof for structural integrity and the visible roof.

Site 3: Modeling: Refining the door and the roof [+ Link Here]

In the third instalment of this series Gene focuses on fixing a problem with the door, take note, after he had already built it, and focuses on refining the final roof structure.

Site 4: Modeling: Simple Fixture for Roof [+ Link Here]

Gene shows the fixture he built for measuring and cutting the roofing boards.

Site 5: Modeling: Wilson Underframe Construction [+ Link Here]

Gene goes on with the build this time focusing on the under frame.

Site 6: Modeling: Progress on the Wilson reefer [+ Link Here]

Gene continues with the under frame, focusing on building the bolsters.

O Scale switcher – the longest project in modelling history

In the beginning…

A long time ago, in a modelling landscape far, far away… there was a UK Model Trains magazine (I cannot remember the issue) that described the conversion of the Atlas O scale Plymouth switcher; the aim being to turn it into an industrial UK shunter.

If my memory serves me well it would have been about 1982 or there about. In short order I found myself owning four of these locomotives, and set about modelling the shunter as I’d seen it a couple of years previously. Having said all of this the title of this article now becomes important because I am about to finish the project that I started sometime back in the early to mid 1980s, in the mid 2010s. Yep – that’s 30 years.

That ‘Model Trains’ magazine article suggested either:

- Keeping the cab height the same as it was on the original model and raising the buffer beam height to allow for buffers etc. or

- Raising the entire cab by about a scale foot and raising the height of the footplate at the same time to allow for buffers to be mounted on the end of the frame.

I chose the second option as I wanted a snappy looking locomotive and not something half thought out that I’d never be happy with. So with magazine, (I have the copy somewhere and I’ll update the article details when I have them) plasticard, liquid glue, files and a sense of adventure I started working on the model.

I left the length of the loco as it was, and raised the body height with a conveniently wide piece of plasticard stock to get the height visually right. In reality that was the easy part as you’re just adding that to the bottom of the body.

All images are Copyright Andrew Martin 2015 unless otherwise noted

In the four photos of the unmodified model note the squat nature of the body. The last photo shows the difference in height between the modified and original loco that the two 40 thou shims of plasticard give. It should be noted that the loco models that I have come with a textured surface on the footplate simulating a safety tread pattern. This was sanded down and removed prior to installing the higher floor.

Next I cleaned up the four pane windows and made them single pane. Finally I sanded down and covered over the buffing faces on the loco ends in preparation for the 3 link couplings and buffers. The only problem was that having put all of that work into the loco – it did not look right to me. It looked like a higher roofed American loco and not something that would have been made in or for an English railway, especially a Quarry railway which I’d always wanted to model (and still do). So it was back to the drawing board.

The second coming…

Unfortunately I only have photos from the second rebuild that I started in 1996 or there about and none from that first effort as it was back in the early 1980s and I don’t remember owning a camera at the time (being a poor electronics apprentice).

Before I begin any modelling project (I over think them to be honest) I do a lot of work on how the final model will look; This locomotive was no different. First was a working sketch that I scanned recently and cleaned up below. (Yes I store all my sketches of train models.)

There are some differences between the concept sketch and the final model that I’ll be completing in the next week or two – overall I’ve come pretty close to what I wanted. I’ve not bothered with the end rails and chain nor the MU stand. As the quarry locomotives were generally run individually and not in MU service in the UK from what I can gather. Additionally I took about 10 mm off the rear end of the unit since I did not want the air tank or a balcony on that end with the new look.

The changes

If it’s blue, it’s not new. The bubbly mess of plastic in the cab end of the hood is what happens when you try and speed up curing of putty with an incandescent bulb. The stove pipe chimney was the result of that and not planned. However, I did add 5mm in the front of the hood to extend the hood forward and rebuilt the front top are of the hood too as the bulky light on the original just irked me too much to live with. The entire cab roof, and rear wall was sawn out, and a plasticard cab end and roof was put in its place. This sounds fairly straightforward, until you see the amount of work that actually went into designing and building the new cab end.

Photo 2 above shows the planning and work that went into the design of the new cab. When the skin (10 thou plasticard) went on it was measured and cut in one piece to ensure that there would be no visible seams on the face of the loco. This went off without a hitch and I learned a lot out of that exercise that has helped me in my model building since. Photo 3 below shows what the cab looks like after the skin has been cut and glued in place.

Also in Photo 3 above you’ll note the

- Oleo buffers (from House of O Gauge in the UK – now gone I believe). These are working buffers and work as well as they look.

- The electrical conduit to the light is fine solder Super-Glued in place. The light is a square styrene section with a circular section cut into the square frame and then drilled out to accept an LED. This will go back into the cab and into the DCC board. I had thought about having a duel sealed beam set, but I liked the look of this better.

- To remove the need for a rear facing horn, I cut a small slot into the top left of the cab for the horn. I’ve yet to place a horn placed on the front of the loco.

- The three link couplings are also working with draw gear behind them on the front and the back. Finally the electrical junction box is a 1:48th MU cover glued on to the face.

- Finally the window frames are all 20 thou and allow a 0.5mm overhang into the window space. I am hoping to get some microscope slide covers cut and put in place in all of the windows. Should that prove too bothersome I will cut out some Monitor protector plastic that I’ve saved from work and use that in its place. It will be secured in either case by Revel clear cement.

It’s getting late, so I’ll just add a couple more photos. If you have questions let me know in the comments and I’ll answer them for you.

I’m not sure if I am going to leave the running gear showing like this or turn it into a tram loco. But the tram idea has me in its grip at the moment.

The fuel filler and gauge are from a 1:48 scale add on kit I’m using on my GP38-2 rebuilds.

Well – that’s it for now. Talk to you all later.

Site seeing – February 14 – with a difference

Site seeing with a difference this St Valentines Day. The family headed for the ocean today to Geelong Victoria. While we were down that way I took the opportunity to visit K & L Model Railways Hobbies & Model Construction Supplies of 81 Ryrie St, Geelong VIC 3220.

All I have to say is – what a surprise. The shop is small, but what it lacks in floor space it more than makes up for in stock. They have a great range of O scale parts, kits and so on.

Had a chat to the owner to the owner this morning and I’ll be back there again once I have a bit more disposable income.

With K & L’s assistance I’ll be building a rake of O scale (7mm:Foot) NSWGR 4 wheel RU Grain wagons (see a photo here: Offsite Photo).

These cars have been on my build list for some times but not being able to find a local source of Brass ‘W’ irons and sprung axle blocks has meant that I’ve had to hold off on the build.

With K & L’s owner assuring me that he can get me everything I need the RU planning process can begin. I expect to build the first body out of styrene, then I’ll cast the remaining bodies before tackling the chassis out of brass section. This will make mounting and securing the ‘W’ irons much easier.

All the best on a lovely ‘cool’ summer Saturday in Ballarat.