Originally posted on the old DasBlog – Thursday, March 28, 2013

While I am not working on the layout of a weeknight, doesn’t mean that I am not thinking on the layout.

My son Ewan (who is 8) got me to thinking about a new layout after a Sunday morning spent switching on a plank I have setup for testing car and coupler heights and and so on. He enjoyed it so much, big smile – the works, that he asked me to build something bigger because he liked driving the loco up to the cars and switching and coupling/uncoupling the cars so much.

He is a mad gamer, and is asking me to help him learn to code so that he can write his own games. So I figured why not make sure that he could “role play” with the locomotives and cars. I have spent quite some time getting the physics of the locomotives right in the decoders and this has formed the basis of my thoughts for the new layout.

What I have currently

I have the following DCC loco’s:

- 2 x Bachmann 70 Tonners (cause I love them – one in Red and the other in Green – and yes they are noisy enough without sound – working on a fix for this in the future)

- 1 x BLI Trackmobile (which moves like honey in summer it is so smooth and oh-so-nice to switch with…)

I have the following DCC & sound equipped locos:

- 1 x BLI EMD SW7 (in UP colours – my Wife’s favourite scheme)

- 1 x Proto 2000 GP20 (also in UP colours)

What all of this means to the emerging layout design is this:

- Long runs where ever possible: This allows the physics that I have programmed into the locomotive’s decoders to come into play. For sound equipped locos I have made sure that the SW7 takes a shorter time to load up before pulling away. This simulates the locomotive gearing, while the GP20 takes longer to load up before moving off for the same reason. Once a loco is moving, having watched a lot of videos on you tube, the power is usually cut and the loco coasts. I can now do the same thing with the Deceleration set reasonably high to ensure that the loco will slow if going up a grade, and maintain or speed up slightly when going down grade. When I need to stop I give a brake application (F7 on my MRC Prodigy Advanced 2 system) whence I get brake squeal, and the locomotive and train stop where needed.

- Proto weighted cars where possible: I use Kadee trucks This ensures that the cars track much better than NMRA weighting standards. I use Kadee trucks under all stock and it they run much better when they are weighted properly to compress the main springs. I use a cubed root formula spreadsheet to track each car type and the weight they should be carrying. One nice side effect is that the clickety-clack as trucks go over rail joints sound much better in my opinion.

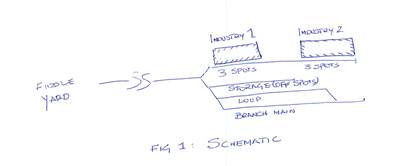

One location that is getting serious design time right now is a Miami Transload Facility. My version would only have three tracks in the Transload facility, the centre one being an overflow (99 off spot according to the SP) track that would also increase the switching.

In the background I am still thinking of adding the bakery that Lance Mindheim wrote about. This effective uses one switch for two long sidings. This would allow the two locations to be switched separately, but different operators that are still within arms reach, and yet still stay true to the area they are modelled on.

During my original planning I had though of extending the design from the 12 foot board through to the 8 foot return board, and using a rotating sector plate (rotates completely through 360 degrees) on the final four foot board with an overhang to provide staging.

Still thinking this over as well as the Boxcar Haven design. More thinking at the moment, will yield a better design in the end. Thanks for following the internal monologue; any comments are always welcome.