I did some measuring on the new track plan (version 3) today and the result is pleasing (at least to me). On the HVRR we use a XAF10 Railbox car as our standard measure for cars; These car’s measure 190 mm over coupler faces – that’s right on the 54′ and some change that a real car has for door spacing if it is recorded as a 50′ car. With the numbers in hand I tried a few calculations to see how everything fit.

Yard Tracks

With measurements now completed on all of the storage and “yard” tracks our holding ability on all tracks suggests that the:

- Main (at 1400 mm) can clear 7 standard cars,

- Loop (at 1500 mm) can clear 8 standard cars.

- Classification track 1(at 1800 mm) can clear 9 cars ,

- Classification track 2 (at 1300 mm) can clear 6 cars, and

- The total on-track yard capacity is 30 cars (not including the interchange as I consider the interchange loadings to be a part of this number).

Yard Occupancy

I don’t want to flood the yard on any one day so I expect that the total yard occupancy at maximum will be 50% of the total – leaving me with 15 cars maximum. So that even with a full train of 9 cars coming in from the interchange I can use Class 1 & 2 to store all of the cars and leave the main and the loop free to work. More on this though below.

Industry tracks

On the main board there are two industries:

- Industry 1 is 800 mm long and can manage 4 cars

- Industry 2 is 1600 mm long and can manage 8 cars

- Interchange track (at 2400 mm) can clear 9 cars plus the loco. The interchange track is considered an industry also.

The trackage on the base of the L are to be built based on an article in Model Trains International #58, page 106 by Bruce Petty. While this was essentially an article on scratchbuilding the Strongheart Packing Co. there was also a track diagram included. While I cannot post the magazine article here for you, I can point you to Bruce’s website which has the same information and track diagram (link here)

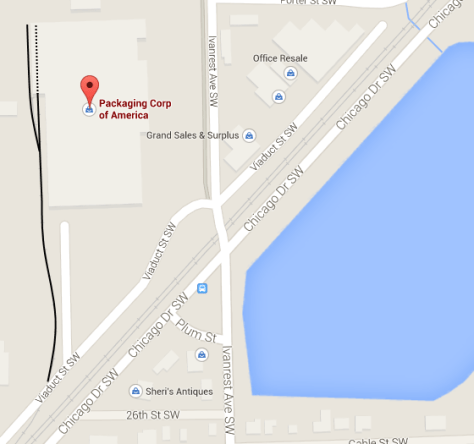

The current track layout in this area bounded by East 49th and E 50th Street is somewhat different from that of 25 – 35 years ago, this is reflected in the two images here:

Image 1: Block bounded by 49th & 50th Street, and Gifford To Corona Ave

This is an overhead view of the same block as in the article, but several of the buildings have been removed; specifically Union Malleable and Strongheart Packing. Otherwise the track for the most psrt seems to be intact.

Another overhead view showing a slightly different angle that puts the article map in perspective.

I’ll be leaving building’s in place at Ingle Bros. It is a nice, generic building, plain brick that will be easy to model. It will have the two car spots as on the plan. The Chase Bag Co will go. In it’s place I’m going to put a team track. This will ensure that I can have a range of cars in that spot, and in addition give a great view of the remainder of this section of the layout.

The other buildings will be changed slightly to give that 1970’s renewal look of tilt-up concrete construction so prevalent in Texas.

Industry occupancy

Just as for the yard, I do not want to flood the industry tracks with cars. There are two reasons for this:

- I like that industries are not always blocked with cars – this is also very prototypical, and

- I am aiming at maximum to have industries be 50-60 percent occupied

Thus the total car numbers of the main board will be:

- Industry 1 holds on average 2 cars with a maximum of 3 cars

- Industry 2 holds on average 4 cars with a maximum of 5 cars

- Interchange holds on average 5 cars (rounded up from 4.5) to 7 cars.

As noted earlier it can clear up to 9 cars at any one time if needed; this ensures that the interchange and the yard tracks should never be flooded with cars to stop the operations of the railroad.

The industrial park (bottom of the L) boards will hold on average 7 cars using the same occupancy rate. In total then the maximum cars in and out of the layout (should all of the occupied spots be switched on one day) would be 17 cars. Luckily that is not going to happen because these car movements would be spread over 6 days.

I am hoping the average will be in the range of 4-5 cars per session. This meets my goal of a short switching session, but with plenty of interest for me as the crew. More on this later.