Introduction

If you have not seen a tuning fork layout, it is a very simple 1 turnout operation. If you are still not seeing it in your mind, think of the letter ‘Y’. Most of the layouts I’ve seen assume either a mainline and a siding, or two sidings. However, that does not mean little operational potential. I found a video by Thornapple River Rail Series on YouTube [Link is below] this week and it got the creative juices flowing.

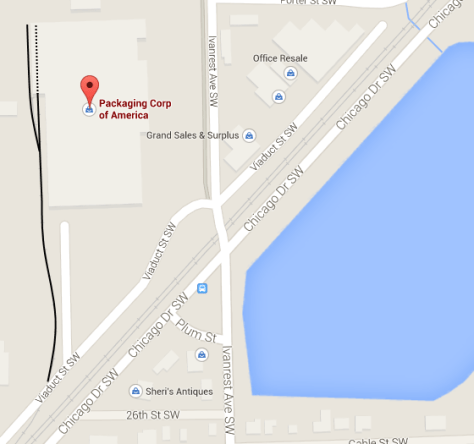

Image 1: The location of the facility from Google Maps

The kicker is that the second of the spurs is used to allow switching to take place on the spur itself. Before you do any more reading watch the video (It is 18 odd minutes long but if you start at about the 4:36 minute mark you’ll get the gist pretty quickly).

Video 1: thanks to Thornapple River Rail Series

Operations

If you start at about the 4:40 mark into the video you’ll see the following occur:

- Loco and first three cars cut off from the train

- Same pulls forward of the spur switch, and reverses across Viaduct St SW toward the plant

- You’ll notice the second spur on the outside of the plant as the train pushes back toward the plant

- Once the roller door comes up, the train pushes back into the dock area, picks up the outbound cars, and pulls forward again to clear the switch for the spur

- Next, the outbound cars get pushed onto the exterior spur

- Inbound cars get pulled forward onto the spur again, the switch is reset, and the inbound cars are pushed back into the dock

- Loco cuts off, pulls forward to clear the switch, and once changed over, pushes back to hook on and pump up the air on the 3 outbound cars

- Pulling forward the loco and three outbound cars cross over the road and re-join the train

- Just to add the cherry on top, the train then reverses back to the yard with the engineer riding the caboose

Now all of this takes between 10 – 14 minutes of video time. But what a fantastic way to spend your 5-20-5 minutes of daily modelling / operating time (read a post on that concept here).

If you want to make it last a little longer, first re-arrange the incoming cars into the order as required by the plant. Additionally some cars may not be unloaded yet, and they need to be moved off-spot, and then back on again with new inbound cars. Some cars may need to be left off-spot on the exterior spur for the next switching session.

Layout idea

While I mainly model in HO my true passion is 0 scale (and bigger when I can manage it). Alas I have not the room for a big layout to run those sized trains – yet.

Image 2: The complete layout (click for a larger version of the file)

For an 0 scale layout I cannot think of a better idea. You could easily do that in 12 feet and no more than 12 inches wide. If you really had the room you could do it in 18 inches wide and go nuts with weathering, winter trees as in the video, and the knocked over Armco barriers. Glorious! The big gotcha here is that the switching lead ahead of the switch has to be longer than 2x the maximum number of cars you switch into the dock. Don’t forget to add a loco length on top of that too.

So if you switch in 3 cars and out 3 cars you’ll need to have six spots plus a loco length to allow the switching to take place.

Hope that this gets your creative juices flowing. And thanks to Thornapple River Rail Series for posting the video. I am going to be looking through a bunch of his videos now for other similar ideas for my layouts in the future.

It’s a sunny and pleasant Saturday afternoon in Ballarat, hope you’re enjoying your day where you are.

Resources:

Google Maps: Location

Bing Maps: Location